The CST730 Anode Ladder Corrosion Monitor is based on the electrochemical impedance testing principle. It assesses rebar corrosion risk and concrete durability by measuring the electrochemical parameters of metallic electrodes (anodes) embedded at different depths within the concrete.

The CP-73 Anode Ladder probe utilizes an array-style ladder sensor design. It investigates the kinetic process of steel corrosion development within concrete by measuring the free corrosion potential of anodes on the ladder relative to a reference electrode, the galvanic current between the anode ladder and a cathode, the resistivity between two adjacent anodes, and the concrete temperature and humidity.

Core Functions

· Free Corrosion Potential Measurement:

Monitors the potential of equally spaced anodes relative to a reference electrode. The potential distribution identifies active corrosion areas, with a sharp potential drop indicating active corrosion.

· Galvanic Current Detection:

Measures the galvanic current between the entire anode ladder and a cathode, reflecting macrocell corrosion effects. An increase in current suggests accelerated corrosion.

· Concrete Resistivity:

Calculates concrete resistivity through AC Electrochemical Impedance Spectroscopy (EIS) between two adjacent anodes. This assesses concrete density and chloride ion permeability. A decrease in resistivity indicates an increased risk of corrosion.

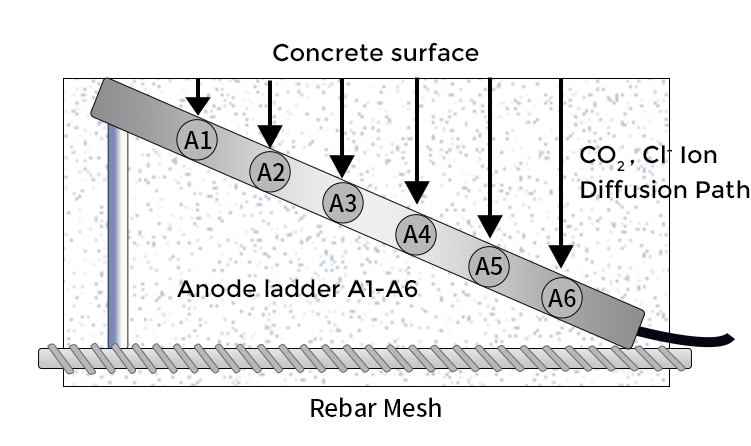

During the concrete corrosion process, the ingress of CO₂, chloride ions, and moisture causes the corrosion front to advance inward. As the depth of the corrosion front increases, the electrode potential, galvanic current, and impedance values of the anode arrays at different depths from the surface undergo significant changes. By analyzing the variation curves of electrochemical parameters from anodes at different depths over time and position, the progression of concrete carbonation depth can be calculated. This allows for predicting the corrosion initiation time of the reinforcement within the concrete, providing guidance for the preventive maintenance of concrete structures.

Figure 1. Schematic Diagram of Anode

Ladder Principle For Measuring Concrete Corrosion Front Progression

Probe Introduction

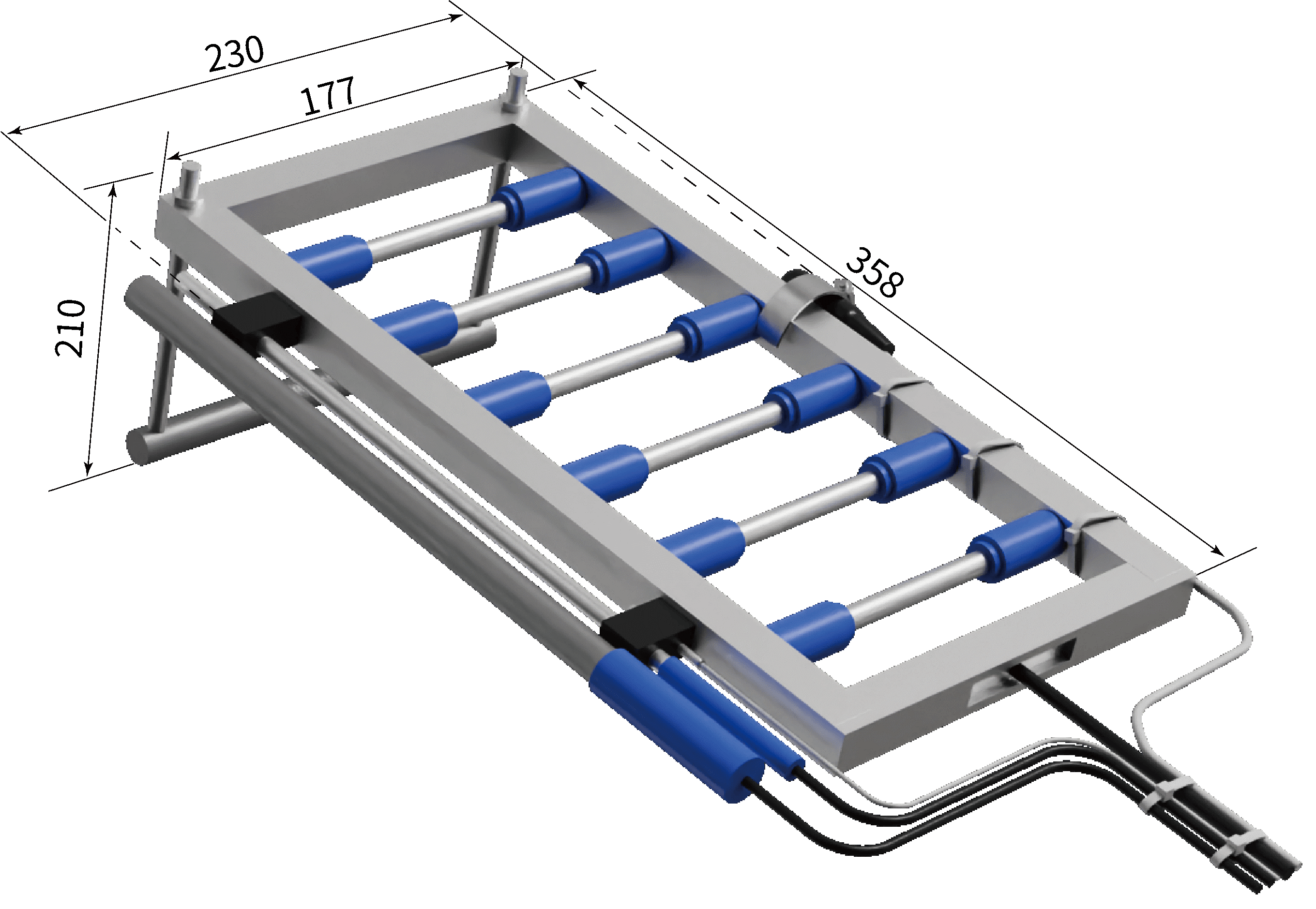

1)Anode Ladder: Features equally spaced anode rods connected by a stainless steel frame forming a trapezoidal structure. A temperature probe is integrated within the stainless steel frame. An external electrode rod (cathode) and a threaded rebar rod are fixed at an appropriate distance for testing galvanic current, polarization current, and concrete resistivity, facilitating research on the concrete depassivation process.

2)Optional: A long-life reference electrode can be installed for monitoring the free corrosion potential of the carbon steel rods.

3)All anodes and cables are resistant to alkali and chloride ion attack, ensuring the long-term durability of the anode ladder probe.

Figure 2. Anode Ladder Structure Diagram

Application Areas

Used for monitoring the carbonation rate of the surface mortar layer in concrete structures (e.g., buildings, bridges), monitoring rebar corrosion rate and development trends, and measuring the free corrosion potential, corrosion rate of carbon steel or stainless steel anodes at different embedment depths, as well as concrete resistivity and temperature.

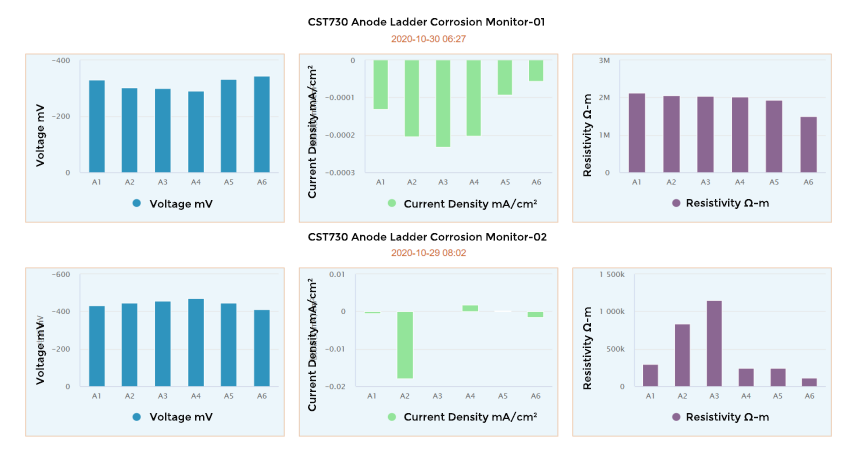

Software Introduction

The Anode Ladder Corrosion Monitoring System software is designed for field corrosion testing. It reads measurement data from the CST730 Anode Ladder Corrosion Monitor and saves it to a database. Test data from different devices can be displayed graphically. Data export to formats such as csv and xlsx is supported. All measurement data and graphs can be easily printed and stored.

Figure 3. Monitoring Data Displaying Rebar Free Corrosion Potential, Rebar Impedance, and Galvanic Current from Anode Ladder

engin@corrtest.com.cn

engin@corrtest.com.cn