The CST480 Series Atmospheric Corrosion Monitor is an industrial-grade sensor specifically designed for corrosion monitoring applications of metal structures such as large server rooms, wind turbine nacelles, and bridges in atmospheric environments. The monitor utilizes precision electrical resistance probe (ERP) technology, combined with AC excitation source technology and a high-precision AV bridge principle. It offers extremely high resolution for metal thinning measurement and automatically compensates for ambient temperature drift, ensuring the stability and reliability of measurement results. It is suitable for continuous corrosion monitoring of metallic materials, displaying corrosion rates and providing corrosion severity classification.

The monitor can be integrated into user management systems via wired RS485 or RJ45 interfaces. It can also transmit data to remote monitoring platforms through GPRS wireless networks. Users can remotely monitor the equipment's corrosion status and early warning information, quantify corrosion rates and levels, and obtain data to support predictions of the remaining service life of metal structures. Based on this data, users can make informed maintenance decisions, ensure structural health, and reduce operation and maintenance time and costs.

Product Features:

Applicable Scenarios: CST480AS is suitable for monitoring corrosion of Cu and Ag metals on PCBs within server rooms. CST480AS-S, CST480MS, and CST4804 are suitable for monitoring atmospheric corrosion of metal structures like bridges and transmission towers.

Precise Measurement: Utilizes high-precision 24-bit AD sampling with an accuracy of up to 1/10,000 and features automatic temperature compensation.

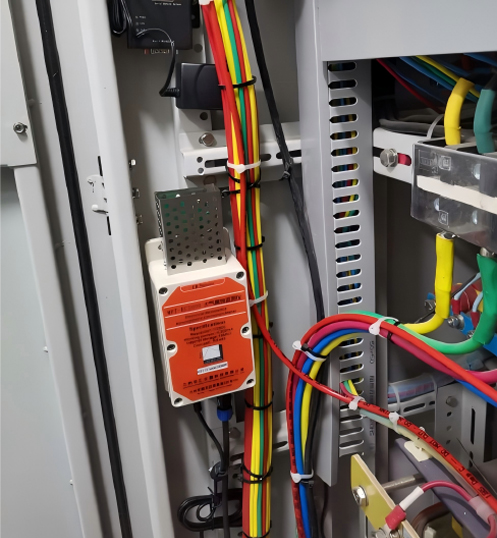

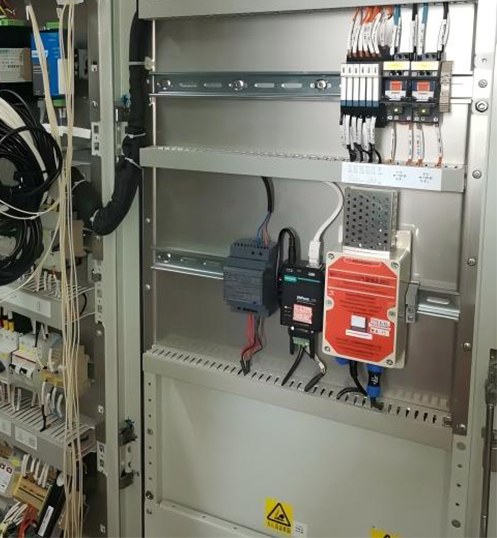

Easy Installation: Includes built-in mounting holes and can also be mounted using rails or clamps based on site conditions.

Rugged Construction: The housing is waterproof, dustproof, and corrosion-resistant, suitable for long-term exposure to the atmosphere and harsh industrial environments.

Strong Compatibility: Employs RS485/RJ45 communication interfaces and the standard Modbus protocol, enabling easy data import into user management systems.

Remote Monitoring:Can be connected to user management systems or cloud server corrosion monitoring platforms via wired/wireless communication solutions, allowing data access anytime, anywhere.

Application Areas:

CST480AS is suitable for monitoring the corrosion of Cu and Ag metals on PCBs in equipment rooms, while CST480AS-S, CST480MS, and CST4804 can be applied to monitor atmospheric corrosion on metal structures such as bridges and transmission towers.

engin@corrtest.com.cn

engin@corrtest.com.cn