Product Introduction

The CST720 Concrete Corrosion Monitor is a real-time, online monitoring device designed for reinforced concrete corrosion. It utilizes an embedded multi-parameter concrete monitoring probe to measure key parameters in real-time, including concrete resistivity, chloride ion (Cl⁻) concentration, pH value, half-cell potential, and steel reinforcement corrosion rate. It is widely used for the online monitoring of steel corrosion rates in concrete structures such as buildings, highways, bridges, and tunnels. The CST720 serves as a powerful tool for field monitoring of steel corrosion and concrete chemical environmental parameters, enabling the prediction of structural durability, safety, and service life of reinforced concrete.

The CST720 Concrete Corrosion Monitor is powered by an AC source via a DC12V power adapter. Measurement parameters and automatic logging intervals can be configured via a PC. Measured data is automatically stored in non-volatile memory.

Figure 1. CST720 Concrete Corrosion Monitor Multi-Parameter Probe

The CP-72 Multi-Function Reinforced Concrete Corrosion Monitoring Probe integrates a pH electrode, a Cl⁻ ion-selective electrode, and an electrochemical three-electrode system into a single, compact unit. It is easy to install and enables simultaneous, in-situ, non-destructive monitoring of pH and Cl⁻ concentration in concrete, as well as the status and corrosion rate of the embedded steel reinforcement. The probe incorporates a long-life MnO₂ reference electrode, a Cl⁻ ion-selective electrode, a conductivity cell, corrosion measurement electrodes, and a temperature sensor. It is designed for embedding within concrete structures for long-term health monitoring.

Figure 2. CP-72 Multi-Function Probe

Application Areas

Utilizing an embedded multi-parameter concrete monitoring probe, the CST720 is suitable for periodic inspection and measurement of Cl⁻ concentration, temperature, pH value, half-cell potential, resistivity, and steel reinforcement corrosion rate in concrete structures such as buildings, highways, and bridges. The system is microprocessor-controlled and performs fully automated measurements.

Technical Indicators

| Model | CST720

|

Input Impedance

| 1×1011Ω |

Corrosion Rate Measurement Range | 0~10mm/a |

| Potential Measurement Range | -2.5~+2.5V |

Potential Measurement Accuracy | 0.5%@FS |

pH Measurement Resolution | 0.1mV |

pH Measurement Range | 4.00~14.00 |

pH Measurement Accuracy | 10%@FS |

pH Measurement Resolution | 0.01 |

Cl⁻ Measurement Range | 0.0001~0.1mol/L |

| Cl⁻ Measurement Accuracy | 10%@FS |

Cl⁻ Measurement Resolutio | 0.00001mol/L |

Resistivity Measurement Range | 10Ω.cm~100kΩ.cm |

| Resistivity Measurement Accuracy | 0.5%@FS |

| Resistivity Measurement Resolution | 0.1Ω.cm |

| Real-Time Clock Accuracy | < 1 minute/month |

| Storage Capacity | 2 Mbytes,stores up to 20,000 data sets |

| Communication | RS485,Standard Modbus Protocol |

| Power Supply | DC12V |

| Dimensions | 180mm×130mm×60mm(Instrument) Φ54mm×116mm(Probe) |

| Weight | 1.5 kg |

Operating Temperature | -30°C~60°C |

Operating Humidit | ≤95% |

Housing Materia | Weather-resistant Engineering Plastic |

Protection Rating | IP65 |

Instrument Configuration

1)CST720 Concrete Corrosion Monitor*1

2)CP-72 Multi-Function Corrosion Monitoring Probe*1

3)CSKit Corrosion Monitoring Software*1

Application Cases

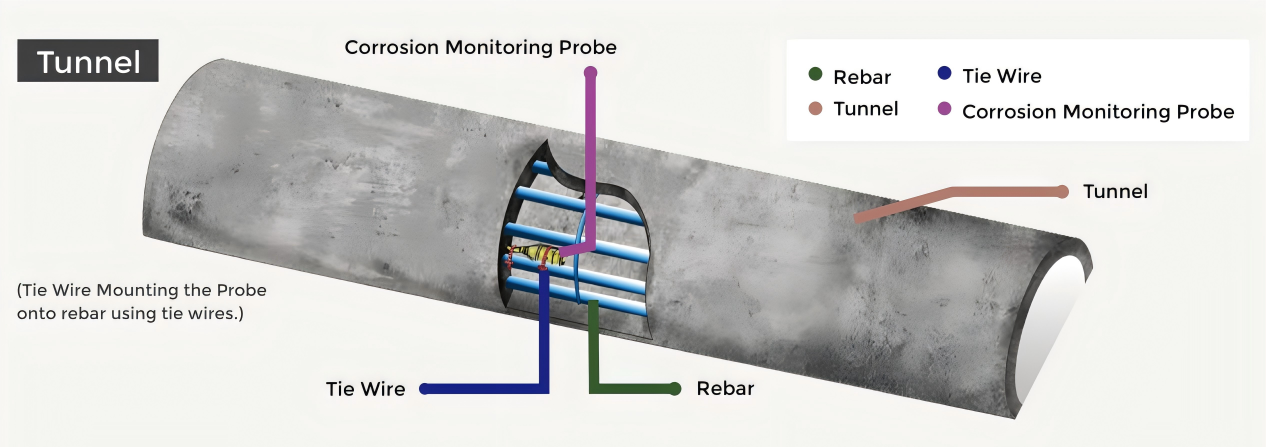

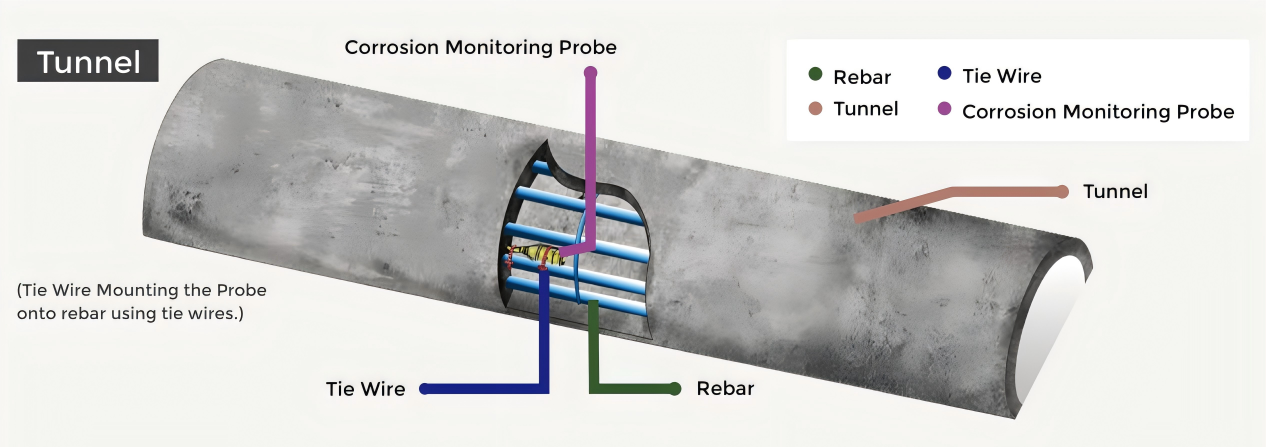

To ensure the structural safety of major underground facilities such as tunnels and subways, this project has deployed an advanced wireless monitoring network for reinforced concrete corrosion, utilizing CST720 concrete corrosion monitors and CP-72 multi-function probes. The core objective of the system is to capture real-time corrosion dynamics within the structure, enabling direct monitoring of the rebar's self-corrosion potential, polarization resistance, and corrosion rate, while accurately collecting key environmental parameters including chloride ion concentration, pH, and resistivity within the concrete.

By integrating on-site sensors and fiber optic routing equipment, all data are wirelessly transmitted to a central monitoring server, allowing management personnel to remotely inspect the corrosion status of rebars and the deterioration of concrete in various structural zones without being on-site. The system not only supports scientific evaluation of the overall corrosion and protection status through statistical methods but also automatically triggers email or SMS alerts to managers upon detection of abnormal rebar corrosion. This enables full-cycle intelligent management-from long-term tracking to immediate warning-thereby providing robust data support for the durability and operational safety of critical infrastructure.

Figure 3. Installation Diagram of Concrete Corrosion Monitoring Equipment at a Typical Cross-section of the Tunnel

engin@corrtest.com.cn

engin@corrtest.com.cn