The CST400C Electrical Resistance (ER) Probe Corrosion Monitor is designed for onsite corrosion monitoring of pipes and vessels delivering gas, water, oil and multi-phase fluids, providing data such as corrosion rate, corrosion loss, and corrosion allowance. It employs high-speed, low-power MCU and high-precision, low-power 24-bit ADC with resolution up to 0.06/1,000,000. Thanks to AC excitation source technology and AV bridge principles, it can achieve high-resolution micro-resistance measurement, with corrosion resolution reaching 0.01% of the sensing element's total thickness. Built-in temperature compensation circuit minimizes the impact of temperature fluctuations on results.

The CST400C uses industrial-grade components and an IP67-rated enclosure, with all interfaces designed to be waterproof for field work. It complies with international explosion-proof standards, including ATEX 2014/34/EU Directive – Annex III - Module B, EN IEC 60079-0:2018+A11:2024, and EN IEC 60079-11:2024. It carries the explosion-proof marking Ex ia IIC T4 Ga and is suitable for Zones 0, 1, and 2, as well as areas with explosive gas mixtures of temperature classes T1 to T4.

CST400C adopts RS485 communication. CST620 Handheld Data Downloader can be used to manually download data locally. Data can also be transmitted to the terminal's control center through a wired network formed by communication cables, or via CST610 wireless data transceiver with a commercial wireless network. The Modbus protocol or user-specified protocol can also be used to connect the corrosion monitoring data to the user's comprehensive data management platform.

Corrosion status can be monitored in real time through corrosion data analysis softare. The instrument features a high-precision real-time calendar clock for timestamping data points. It is powered by a DC 12V supply.

Figure 1. On-Site Installation of the CST400C

Probe Introduction

Electrical Resistance (ER) probes are categorized into Hollow Cylinder (Tube) Probes and Flush-Mounted Planar Probes, as described below:

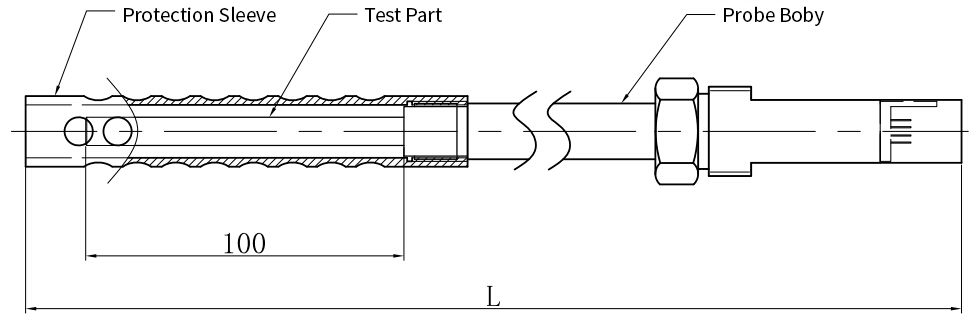

The Hollow Cylinder (Tube) Probe is fabricated from a thin-walled tube made of onsite materials. It offers high sensitivity and precision, and is suitable for applications with pressures up to 40 MPa.

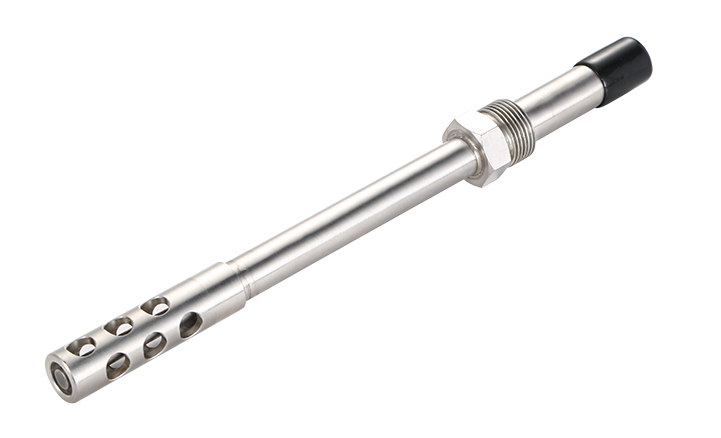

Figure 2. Hollow Cylinder (Tube) Probe

Figure 3. Hollow Cylinder (Tube) Probe Diagram

Table 1. Hollow Cylinder (Tube) Probe Model Specifications

Model | Sensing Element Thickness | Corrosion Coupon Material | Probe Body Material | Pressure Rating |

CP-41 | 5mil/0.127mm | 20#、N80、X65 etc.(Customized per pipeline) | 316L(Default) | 40MPa |

10mil/0.254mm | 40MPa | |||

20mil/0.508mm | 40MPa |

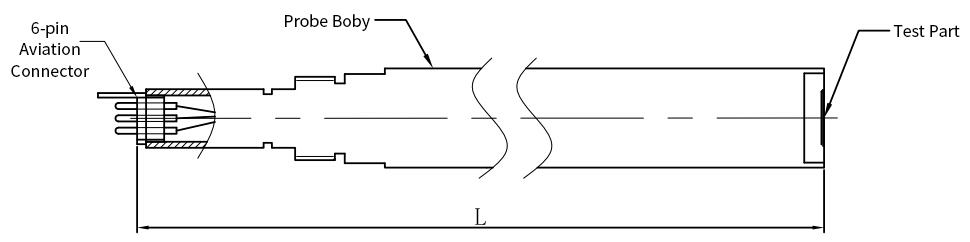

The flush-mounted planar probe is designed for installation flush with the internal surface of a vessel or pipeline, as well as at mid-point, bottom, or other specific locations required for monitoring. It offers high accuracy and is particularly suited for ultra-high pressure or high-flow-rate media, with a pressure rating of up to 40 MPa. The planar probe developed by our company for high-pressure, high-H₂S (sour) environments is a patented product.

Figure 4. Flush-mounted planar probe

Figure 5. Flush-mounted planar probe Diagram

Table 2. Flush-mounted planar probe Model Specifications

Model | Sensing Element Thickness | Corrosion Coupon Material | Probe Body Material | Pressure Rating |

CP-41 | 5mil/0.127mm | 20#、N80、X65 etc.(Customized per pipeline) | 316L(Default) | 40MPa |

10mil/0.254mm | 40MPa | |||

20mil/0.508mm | 40MPa |

Application Areas

Monitoring of metal's total corrosion amount, corrosion allowance and corrosion rate in gas, liquid and oil-water-gas multiphase systems

Software Features

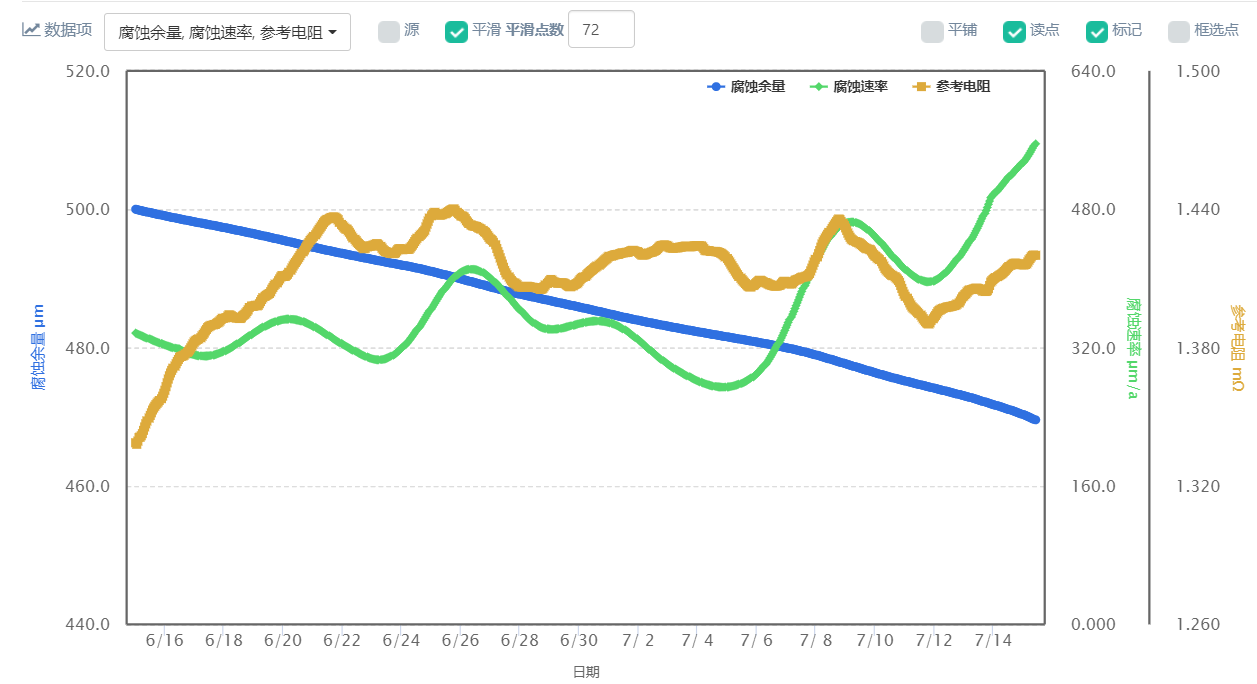

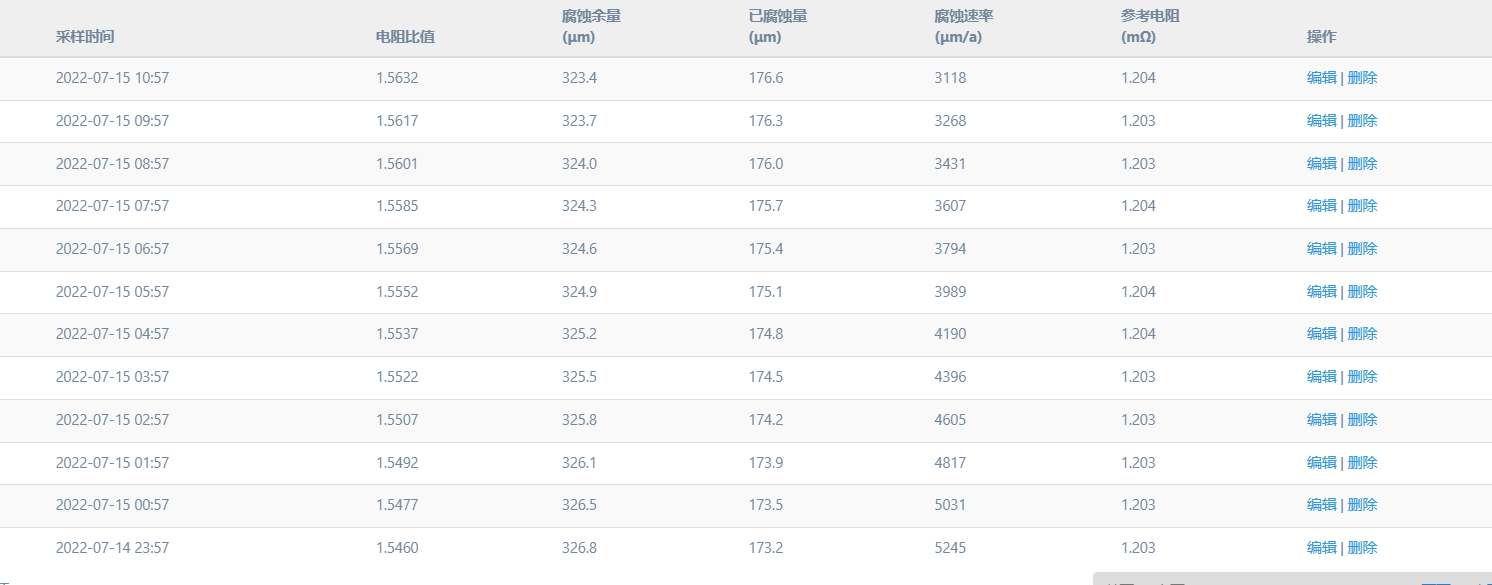

The corrosion analysis software is used under Windows XP or above. The data can be directly imported into the computer for data processing & analysis through CST620. Software key modules include corrosion data management, corrosion allowance & corrosion rate display, graph printing, language switching, data processing &analysis. Based on the differential calculation (linear regression) of the corrosion thinning amount, the software can obtain the corrosion rate, corrosion allowance and corrosion loss during any period, and calculate the corrosion rate, draw the corrosion curve, and export the data analysis report.

The software supports switching between Chinese and English. All data and graphics are importable, exportable, and printable.

Figure 6. Online corrosion analysis software

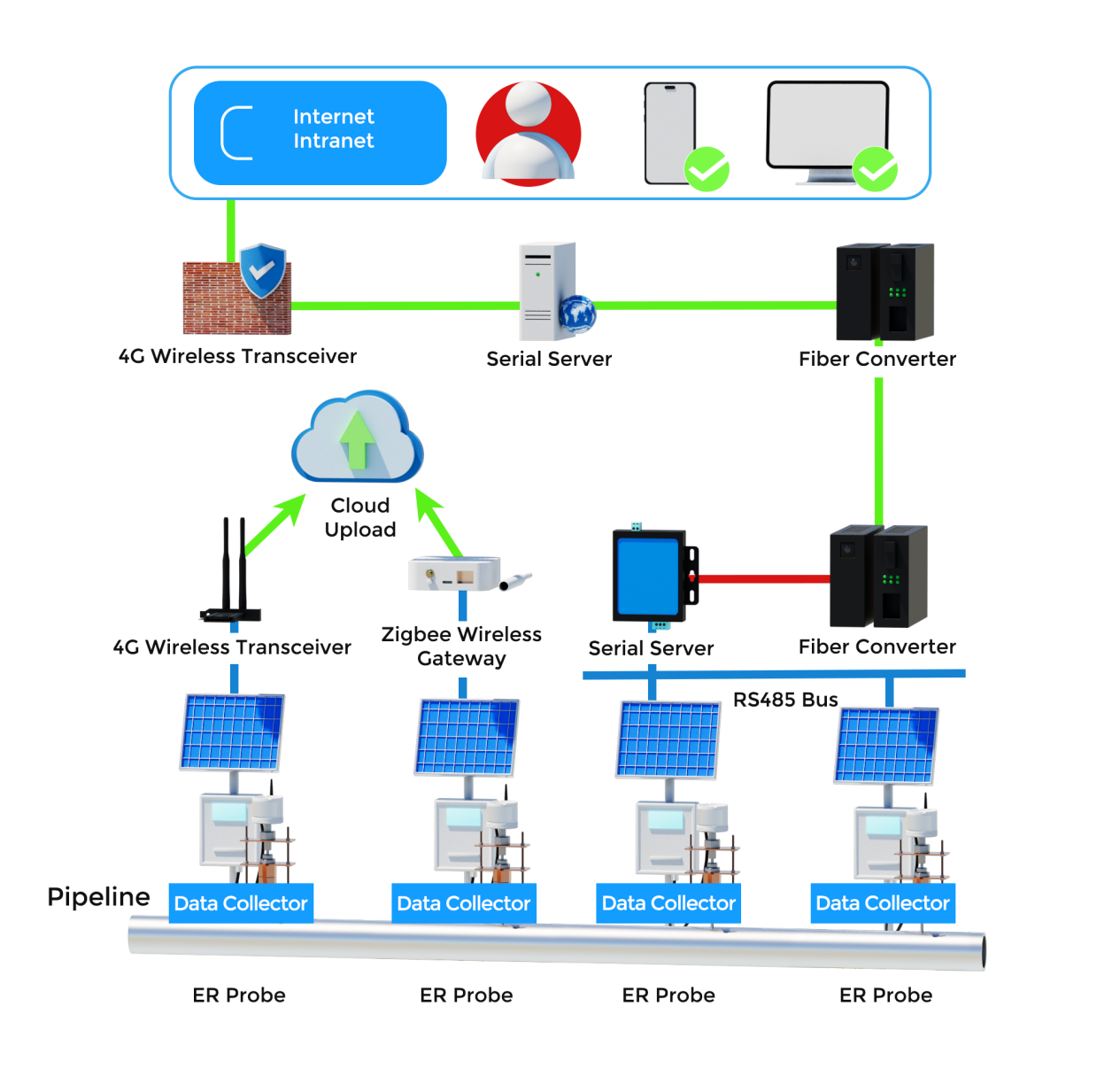

Remote Corrosion Monitoring Network System

A remote monitoring network system can be established using commercial 4G networks, where one or more CST610 wireless transceivers act as RTU nodes for periodic polling of CST400C instruments, and transmit data in real-time to the central control center. Monitoring software visually displays test data from various devices, including remaining thickness and corrosion rates.

Figure 7. Remote Corrosion Monitoring Network Formed by Wireless Transceivers and Cloud Servers

To comply with explosion-proof and other safety regulations, an RS485-based intrinsically safe wired network allows data transmission to the central control center. Manual data download is also available via the CST620 Handheld Data Downloader.

Figure 8. CST400C Pipeline Installation Diagram

engin@corrtest.com.cn

engin@corrtest.com.cn